Page 36 - The Constructor 2017

P. 36

Our Military Affiliations

NEWS FROM HMS LANCASTER

Babcock starts HMS Lancaster upgrade and maintenance programme

CPO ‘Toyah’ Willcock, HMS Lancaster’s Lead Weapon Engineer writes “I am delighted to

have been asked to write an article for the Constructors Journal, giving you an update on

the status of your affiliated ship. Our affiliations mean a lot to the Ship’s Company, and we are

proud to share news of our progress.

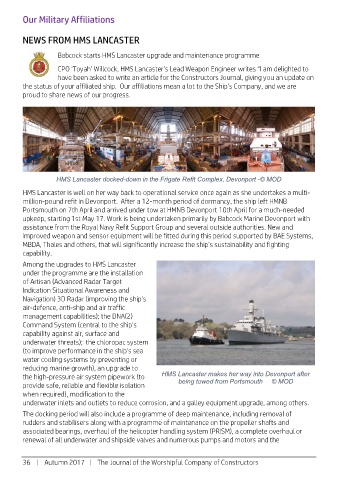

HMS Lancaster docked-down in the Frigate Refit Complex, Devonport -© MOD

HMS Lancaster is well on her way back to operational service once again as she undertakes a multi-

million-pound refit in Devonport. After a 12-month period of dormancy, the ship left HMNB

Portsmouth on 7th April and arrived under tow at HMNB Devonport 10th April for a much-needed

upkeep, starting 1st May 17. Work is being undertaken primarily by Babcock Marine Devonport with

assistance from the Royal Navy Refit Support Group and several outside authorities. New and

improved weapon and sensor equipment will be fitted during this period supported by BAE Systems,

MBDA, Thales and others, that will significantly increase the ship’s sustainability and fighting

capability.

Among the upgrades to HMS Lancaster

under the programme are the installation

of Artisan (Advanced Radar Target

Indication Situational Awareness and

Navigation) 3D Radar (improving the ship’s

air-defence, anti-ship and air traffic

management capabilities); the DNA(2)

Command System (central to the ship’s

capability against air, surface and

underwater threats); the chloropac system

(to improve performance in the ship’s sea

water cooling systems by preventing or

reducing marine growth), an upgrade to

the high-pressure air system pipework (to HMS Lancaster makes her way into Devonport after

provide safe, reliable and flexible isolation being towed from Portsmouth © MOD

when required), modification to the

underwater inlets and outlets to reduce corrosion, and a galley equipment upgrade, among others.

The docking period will also include a programme of deep maintenance, including removal of

rudders and stabilisers along with a programme of maintenance on the propeller shafts and

associated bearings, overhaul of the helicopter handling system (PRISM), a complete overhaul or

renewal of all underwater and shipside valves and numerous pumps and motors and the

36 | Autumn 2017 | The Journal of the Worshipful Company of Constructors